Recycling end-of-life facade glazing

Our network solution

At Guardian Glass, we take pride in using our industry reach and technical insight to foster connections that promote the responsible use of resources. Our end-of-life glass network helps bring together key stakeholders to support the effective collection and processing of façade glass at the end of a building’s life cycle.

A practical, network-driven solution for construction projects

This solution is made possible through preferred recycling partners, aligned to support your project’s resource goals and operational efficiency.

Through this network, investors can benefit from:

A compliant and controlled process

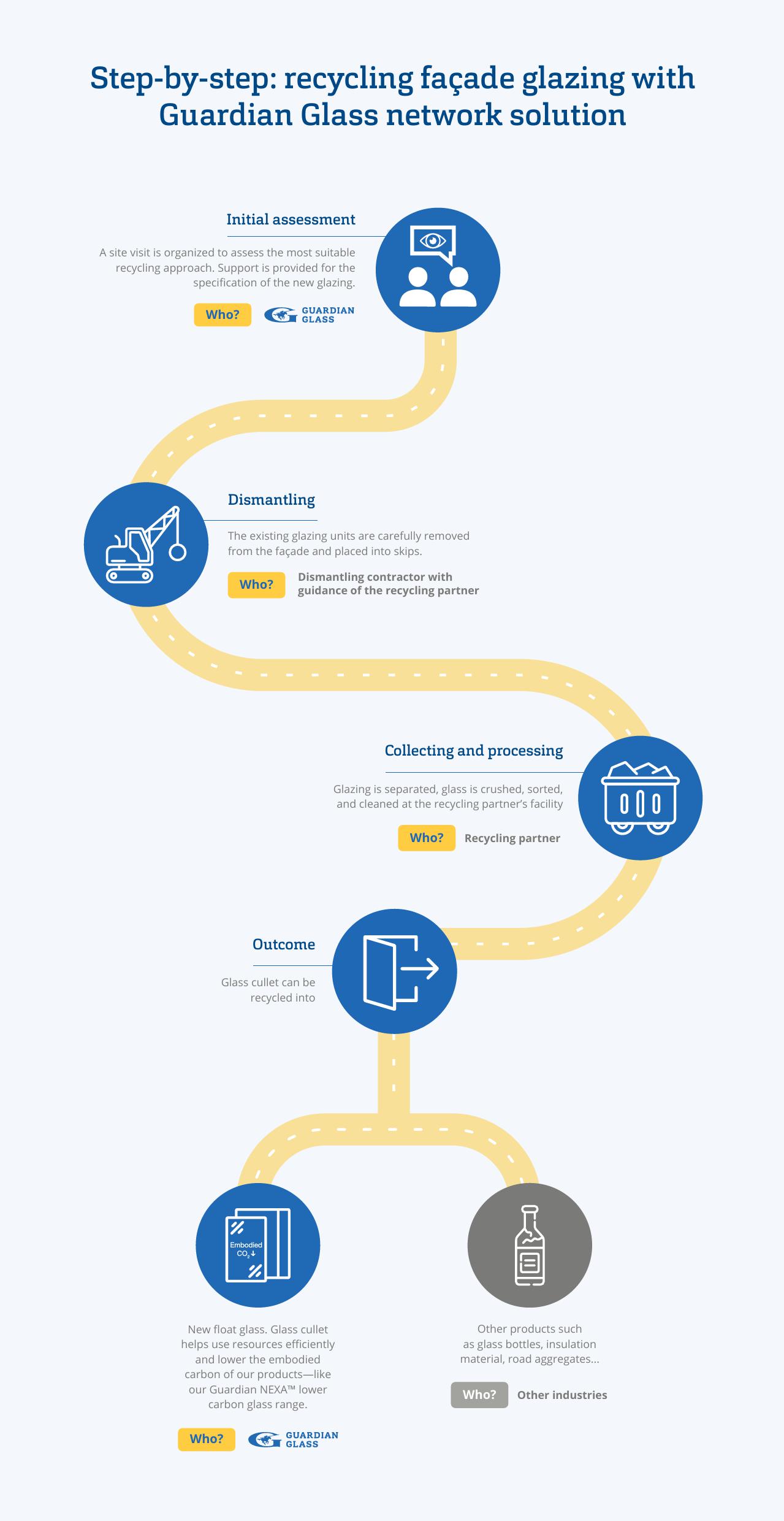

End-of-life insulated glazing units (IGUs) are removed and handled without on-site crushing, reducing the risks associated with glass handling on site. Instead, they are directed to authorized recycling facilities that follow controlled, documented procedures.

Simplified logistics

There’s no need to separate materials: IGUs and other glazing materials*—whether intact or broken—are collected into a single container, streamlining coordination for demolition or renovation projects.

Transparent pricing

Different from other solutions which may require on-site crushing with marginal labor and landfilling, Guardian's solution offers very transparent and predictable pricing all handled by our preferred recycling partners.

Tailored coordination

Every façade project is unique. Guardian’s solution matches the project’s specific scale, location, and timeline. A site visit—either at an early stage with Guardian Glass, or/and one of our trusted recycling partners—to assess the existing glazing and recommend the most appropriate approach for that specific project.

Responsible resource management through advanced processing

Our network collaborators use modern industrial methods to recover as much glass and associated materials as possible from post-use glazing, routing them toward new applications—including float glass production.

Putting Façade Recycling into Practice: The Mountbatten House Project

The Mountbatten House redevelopment combined heritage preservation with improved energy performance by replacing outdated double glazing with high-performance architectural glass. 45 tons of glazing were carefully deglazed, then cleaned, crushed and sorted into cullet at a recycling facility, before being delivered to our local plant.

From recovery to recycling: the value of glass cullet in float glass manufacturing

Collected glass cullet that meets Guardian’s quality and specification standards may be recycled into our float glass production.

Glass cullet plays a valuable role in the float glass manufacturing process. The use of 1 ton of cullet saves approximately 1.2 tons of virgin raw materials such as sand, dolomite, soda ash and limestone. Using cullet also reduces process-related emissions. As it has already undergone the mineralization process, it releases fewer greenhouse gas emissions during melting than virgin raw materials. Every ton of cullet used allows to avoid the need for 2 million BTUs (586 kWh) of natural gas and to reduce up to 700 lbs (318 kgs) of CO2 emissions.

Connecting to Guardian NEXA™ lower carbon glass

Guardian NEXA, our range of lower carbon glass, is one example of what can be achieved with increased cullet use. By helping to route end-of-life façade glass into the recycling stream, this network can contribute to efficient resource consumption, and to reduce the embodied carbon of the built environment.

We’re here to help you explore the right path for dismantling and recycling.